- Location

North Vancouver, BC

- Completion

2021

- Size

7,530 sq ft

- Sustainability

Passive House Certified

1 Lonsdale

This project's innovative prefabricated mass timber party wall sets a precedent, achieving Passive House certification on a zero-lot line infill site. —Jury comment, Canadian Green Building Awards

Welcome to the neighbourhood

Located in the heart of North Vancouver’s Shipyard Distrtict, 1 Lonsdale was designed to complement a bustling community known for its retail, galleries, restaurants, and a comprehensive network of walking and cycling trails. Featuring a main floor restaurant with two floors of additional office space above, the project’s owner was committed to ensuring the new build would achieve high environmental performance while contributing to a dynamic urban realm.

Site constraints and considerations

The adjacent pedestrian activity added to an already challenging project site—a tight urban infill lot flanked by a building at its rear, an alley on one side, and a street on the other two sides. Any construction solution would need to account for the impossibility of an on-site staging area, incorporate a noncombustible party wall, and minimize disruption to the streetscape.

How we built it

The team opted to use a glue-laminated post and beam system with 5-ply cross-laminated timber (CLT) for the roof, floor, and wall panels.

Light Timber Panels (LTD) were prefabricated to exact specifications to meet the stringent requirements for Passive House certification. By minimizing gaps and improving airtightness, the panels will help to achieve up to a 90% reduction in energy consumption compared to a conventional building.

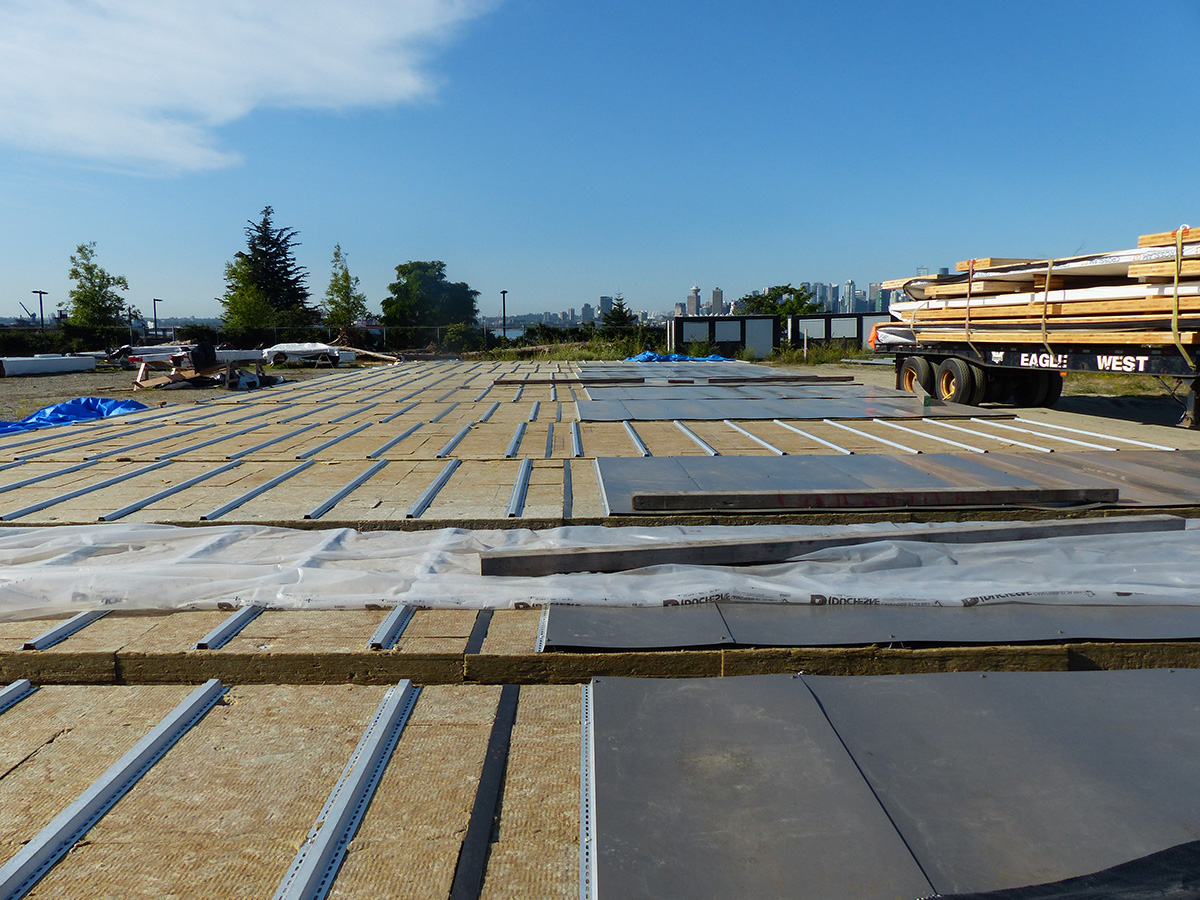

Utilizing a nearby staging yard, Naikoon applied the membrane and insulation on the CLT for the north wall panels, creating full-height CLT envelope facade panels—an innovation for the industry. Materials were then delivered to the jobsite in a just-in-time sequence and lifted in place by crane.

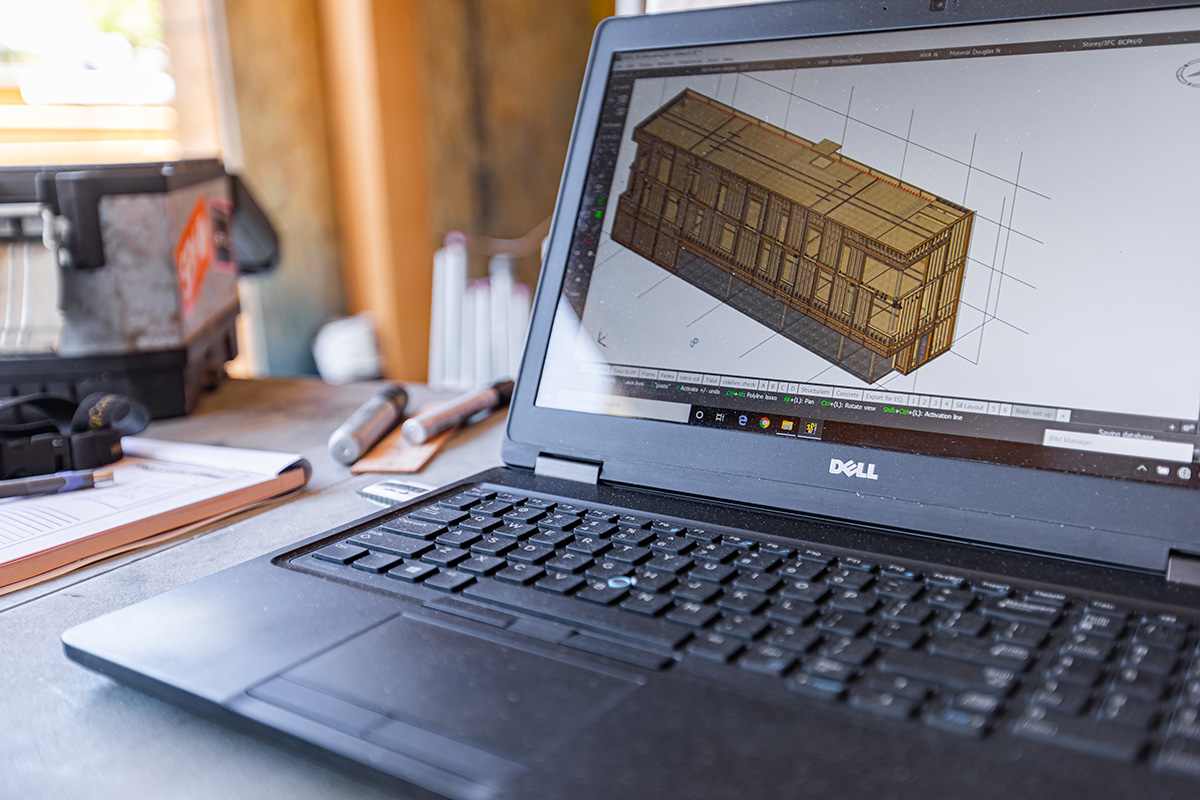

With the help of Building Information Modeling (BIM) and Virtual Design and Construction (VDC) technology, the installation schedule was shortened from 21 to just 10 days, minimizing disruption and achieving significant cost savings for the client. By digitally constructing the building multiple times, the Naikoon team was able to identify and capture installation, scheduling, and estimation efficiencies.

Awards

- 2021AFBC Innovation Award

- 2022Canadian Green Building AwardsCommercial/Industrial (Small) Award

- 2022VRCA Gold award of Excellence for projects up to 20 million

Process

We didn’t ever see Naikoon as simply the contractor on the job. They were with us every step of the way. They shared the idea that buildings can reflect what’s happening today and pay homage to the past while also paving the way for the future. —Krystie and Tyke Babalos, Owners, Babco Equities Ltd

Team

Architect: Hemsworth Architecture

Structural: Equilibrium Consulting Inc.

Passive House: Peel Passive House Consulting

Photography: Ema Peter Photography (Final) and ISHOT (Construction)